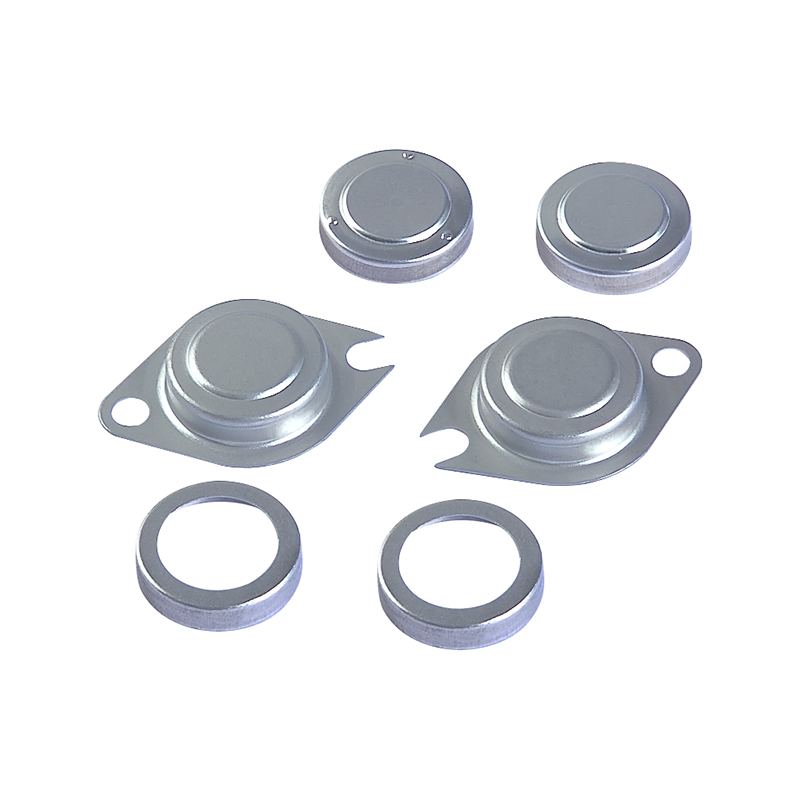

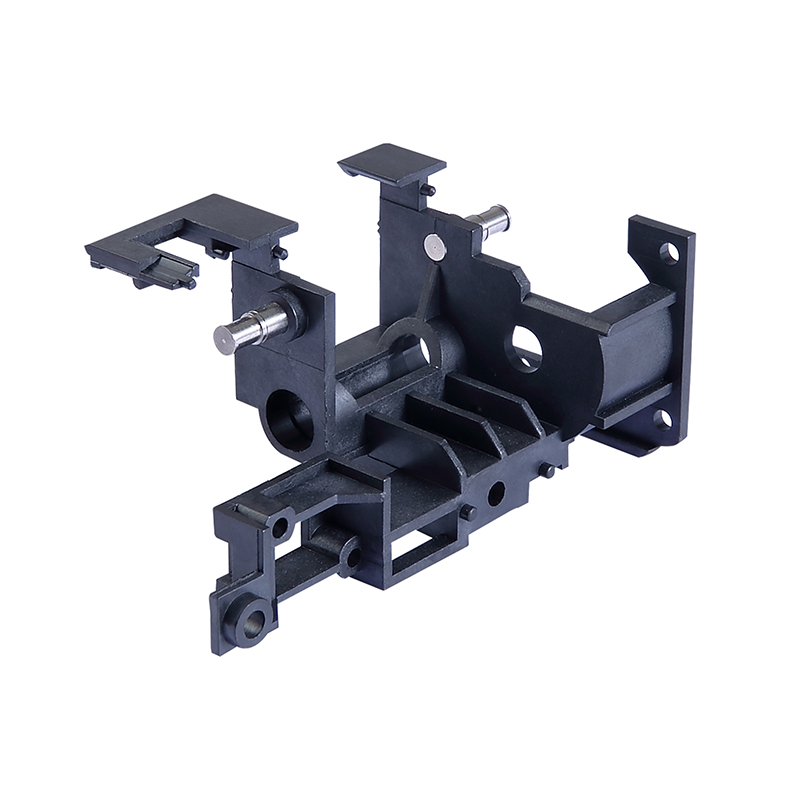

Stamping technology, with its high efficiency, high consistency, and material adaptability, has become the mainstream method for manufacturing metal sensor housings.

- 0086-755-28665057+86-18898723054

- 17685383572@163.com

- No. 185, Ainan Road, Longgang Street, Longgang District, Shenzhen